Cone Crusher

Cone Crusher Application:

CS Symons cone crusher is widely used to crush metaliferous and non-metaliferous ores, such as iron ore, sandstone pebble, limestone, granite, basalt, diabase, cobble, etc

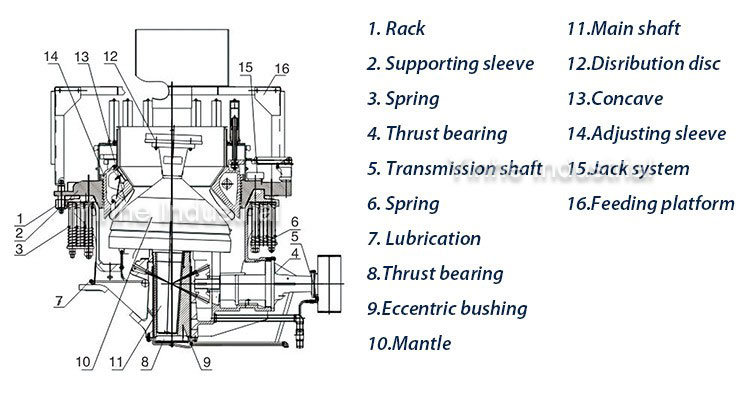

Cone Crusher Structure:

Working principle:

Cone crusher consist of frame, transmission device( countershaft, countershaft bushing, gear and pinion), main shaft, eccentric shaft, cone,mantle, bowl-shaped bearing, springs and hydraulic pressure station for adjusting discharge opening.

(1) Transmission device: Countershaft assembly is supported by the bronze countershatf bushings, can be dismounted for convenience of maintence. And the gear and pinipn with high strengh and high precision are adopted to ensure the reliable operation of equipment.

(2) Main shaft: Forged form hardened and tempered chrome molybdenum steel particularly large diameter to suit wear-resisting application. High quality copper socket liner can bear high crushing load, and allows the machine working under rigorous condition.

(3) Cone and mantle plate, high manganese steel casting, hydraulic lock device is convenient and reliable.

(4) Spring and hydraulic device: Convenient for adjusting the discharge size, can remove the foreign materials if non-crushable objects came into the crushing chamber.

Cone Crusher Technical parameter:

Model | Moveable Cone Dia. | Cavity Type | Feeder Opening Size | Adjusting Range of Discharge Opening(mm) | Main Shaft Speed | Motor Power (kw) | Capacity(t/h) | Overall Dimension L*W*H (mm) | |

Shutting Size(mm) | Opening Size(mm) | ||||||||

CS75B | 900 | Fine | 83 | 102 | 9-22 | 580 | 75 | 45-91 | 2821×1880×2164 |

Coarse | 159 | 175 | 13-38 | 59-163 | |||||

CS110B | 1200 | Fine | 127 | 131 | 9-31 | 485 | 110 | 63-188 | 2821×1974×2651 |

Medium | 156 | 156 | 13-38 | 100-200 | |||||

Coarse | 178 | 191 | 19-51 | 141-308 | |||||

CS160B | 1295 | Fine | 109 | 137 | 13-31 | 485 | 160 | 109-181 | 2800×2342×2668 |

Medium | 188 | 210 | 16-38 | 132-253 | |||||

Coarse | 216 | 241 | 19-51 | 172-349 | |||||

CS220B | 1650 | Fine | 188 | 209 | 16-38 | 485 | 220 | 181-327 | 3911×2870×3771 |

Medium | 213 | 241 | 22-51 | 258-417 | |||||

Coarse | 241 | 268 | 25-64 | 299-635 | |||||

CS315B | 2134 | Fine | 253 | 278 | 19-38 | 435 | 315 | 381-726 | 4613×3251×4732 |

Medium | 303 | 334 | 25-51 | 608-998 | |||||

Coarse | 334 | 369 | 31-64 | 789-1270 | |||||

The raw material is high strength cast iron, with good mechanical property, as well as good ability of absorbing the energy of crusher's vibration. It's a great help to make the rotation of main shaft running steady, which can continuously stable the output of your crusher. The heat treatment of tempering is applied to release the internal stress. It's a great help to prevent the part's dimension change in the daily operation of your crusher. It obviously can prolong the life of your crusher. The final machining is carried by CNC machine to ensure each dimension tolerance, which helps to make your assembly easy and fast, to improve the efficiency of your production and maintenance.

Although it is known for its ability to crush hard and abrasive ores and rocks, the cone crusher is better suited for secondary crushing. It is designed to crush pre-dimensioned materials, generally of 100 mm, 150 mm or 200 mm, and provide finished products of small dimensions.

Tel:+86 18136385621

phone/whatsapp:+86 18136385621

Email:yinheindustrial@163.com

Website:www.yinheindustry.com

Add:High-tech Industrial Park,Zhengzhou City,Henan,China