HGM Medium-Speed Grinding Mill

1.Produce Overview

HGM Medium-Speed ultra-fine mill is an equipment which is specialized in processing andmanufacturing the fine and ultra-fine powder.It has become a excellent mechanical grindingequipment in the mechanical ultra-fine field with strong technical and cost advantages.

2.Application:

The mill is suitable for processing the low and intermediate hardness brittle materials which arenon-flammable and non-explosive,such as calciumcarbonate,kaolin,bentonite,talc,attapulgite,barrite,gypsum and graphite and so on.So far,it hasbeen widely applicated in paint,papermaking pigment,rubber,plastic,filler,cosmetic,chemicalsupplies and many other industrial fields.

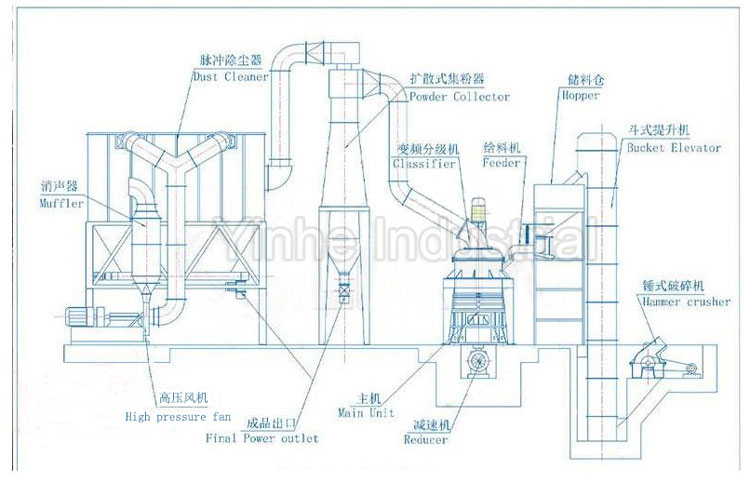

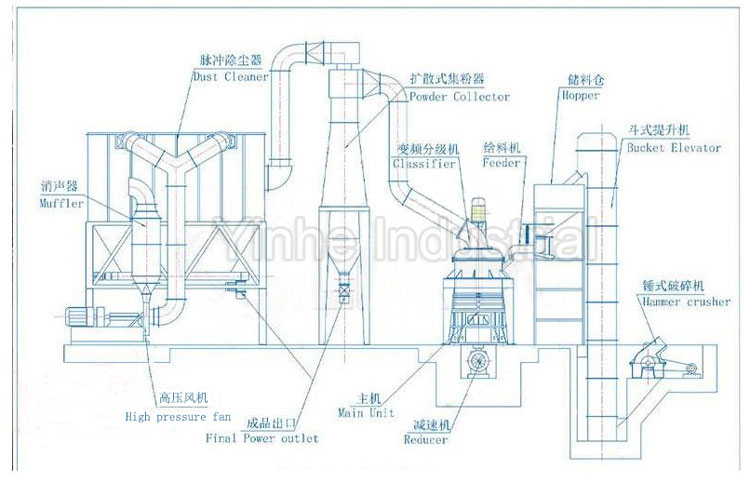

Drawing for reference

3.Technical Advantages

A.It features high efficiency and low energyconsumption,with the capacity more thantwice that of jet mills but the energyconsumption lower by 30%The Rollers and rings are forged from specialmaterial,which increases the durability byseveraltimes. B.The grinding chamber has no bearingscrew,and is able to work stably free ofvibration afterbalance treatmentThe efficient vertical turbine powderclassifier can achieve highefficiency,accurate cutting size and nospillover of coarse powder. C.Frequency-conversion control,convenientfor the adjustment control,with the one-timefinished products D97≤5umAutomatic feedback with fast and stableconversion of finished products;intelligentcontrol,saving labor costs directly. D.The efficient double powder collectingmethod of powder collectors and pulse dustcollectors are able to achieve good effectin dust collection,which is far higher thanthe international standard.The optimized sound insulation room andmuffler can effectively prevent the spreadof equipment noise |  |

4.Working principle

During working,the main motor drives the main shaft and grinding disc to rotate via the reducer and the roller pin on the edge of the grinding disc drives many grinding rollers to roll in the millroller path.The materials into the inner part of main mill via the feeding equipment will fall onthe scatter tray on the rotary plate,moving sidewards under the action of centrifugal force,andthen falling into the mill roller path for being crushed and grinded between the ring androller,after being processed through layers of roller paths,the materials will becomepowder.Simultaneously,the high-pressure fan will inhale outside air into the mill body,thentaking the grinded materials into the powder classifier.The rotaing implellers in the classifier will drive the coarse particles to fall back for repeatedgrinding,with the qualified fine powder forced into the cyclone powder collector along with theair flow and discharged from the lower discharge valve as finished products,while the air flowwith a small amount of fine dust will be discharged out of the mill via the blower and mufflerafter being purified by the impulse dust collector.

5.Full line flowchart:

6.Technical Parameter:

| Model | HGM-80 | HGM-100 | HGM-125 |

| Average Diameter(mm) | 800 | 1000 | 1250 |

| Max feeding size(mm) | 10 | 10 | 10 |

Finished product size

| Micron | 5-45 | 5-45 | 5-45 |

| Mesh | 325-3250 | 325-3250 | 325-3250 |

| Capacity(kg/h) | 600-4000 | 900-6000 | 1500-10000 |

Motor power (kw) | Host | 75 | 132 | 185 |

| Classifie | 18.5 | 30 | 75 |

| Fan | 45 | 75 | 110 |

| Feeder | 3 | 4 | 5.5 |

| Dischargevalve | 0.75 | 1.1 | 1.5 |

| Overal size(mm) | 13.9*4*6.2 | 18*4.6*8.6 | 19*6*9.5 |

Weight(t)

| 18 | 22 | 36 |

7.Machine Pictures:

If you have any other problem or comments,please let us know.

We are on time 24 hours*7.

We can offer free design solution and drawings based on your requirements.

Free installation and debugging manual,operation manual will besupport when or after loading goods into containers.